The first e-commerce of marble, granite and natural stone

Is something not clear to you?

Contact our customer service department:

+48 799 799 798

+48 799 799 798

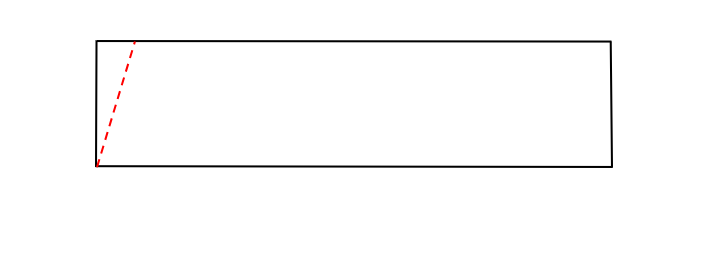

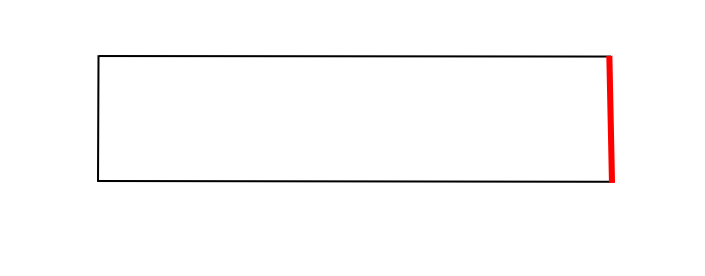

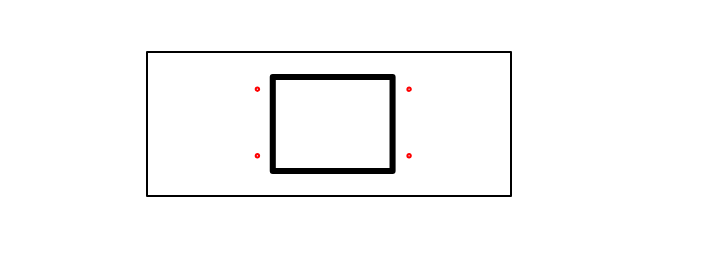

The drainer is nothing more than an incision made in the lower part of the sill and serves as a drip breaker.

This simple but ingenious solution keeps water from flowing from under the windowsill to the adjacent wall, thus preventing unsightly wet patches and the formation of mould and dirt stains.

The drip edge is set back from the vertical rib, i.e. the outermost point, by about 1.5 cm.

Our drainers have a thickness of 9 mm and a depth of 5 mm to allow water to drain away quickly even in heavy rain.

When to select the drainer while purchasing your window sill?

The selection of the drainer from the drop-down menu should be made when the sill you wish to purchase is to be placed externally, and therefore it is superfluous to select this processing for all internal counter sills.

Discover all our sills made from different Marbles, Granites and Natural Stones.

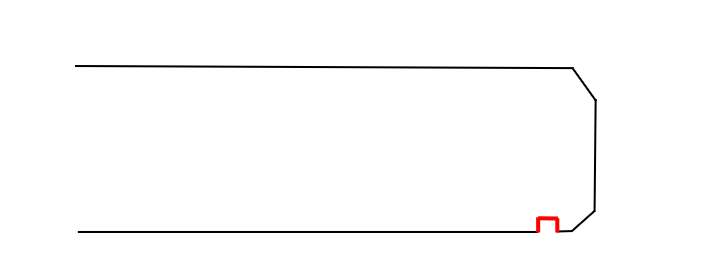

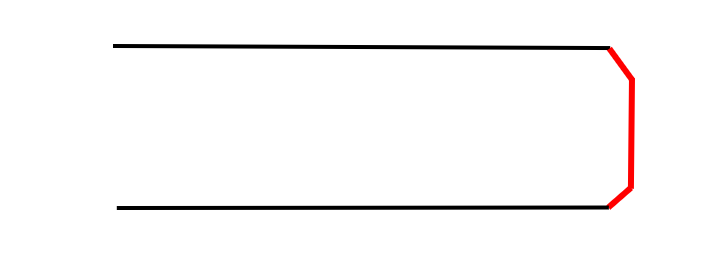

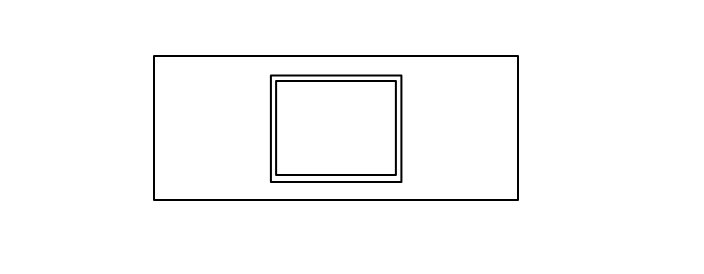

“Visible frontal edge processing” means that the front cutting part (the edge) of your future sill is visible and must therefore be properly finished.

A chamfer is then made on both the top and bottom of the rib, this chamfer will be 45 degrees with a length of approximately 2mm.

Subsequently, to prevent the part between the two bevels from remaining rough, it is polished (in the case of the polished top choice) or sanded.

This makes for a more aesthetically pleasing edge and also has the function of making the edge easier and simpler to clean.

We strongly recommend selecting this type of workmanship for any type of window sill; for both interior and exterior window sills so that you receive a made-to-measure product made to perfection.

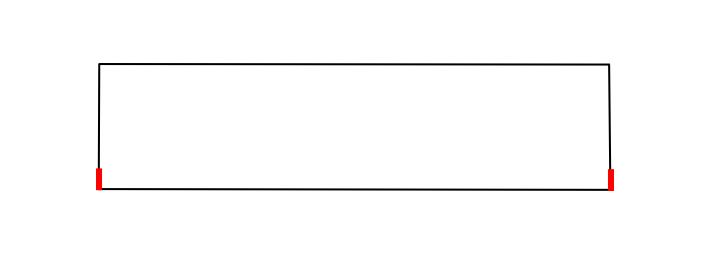

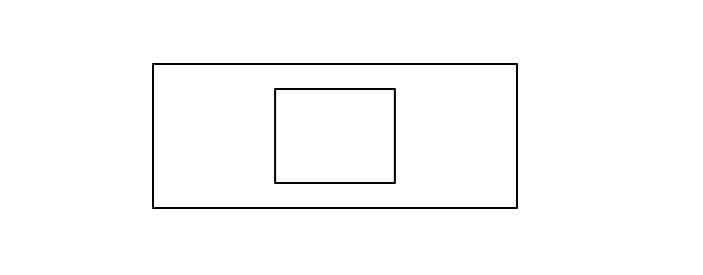

If we look at an installed windowsill, the vast majority of the time we will notice that it protrudes from the wall by a few cm.

The vertical parts that are at the left and right ends and that protrude from the wall are the so-called ‘lapels’.

For that part, for our sill to be perfectly finished, we must perform the same processing for the visible part that we performed on the rib.

We will therefore select “lapels” in our configuration each time our sill protrudes from the wall. Only in rare cases, i.e. when the sill is flush with the wall, is it not necessary to select the processing on the lapels.

Visible head means that one or both short sides (e.g. of a riser) are visible and therefore have to be finished and not left unfinished.

In the case of a cover, the choice of having the drainer on the visible head can also be selected.

In kitchen countertop risers, ‘visible edge’ means that one (or more) of the ‘free’ sides (which do not rest on the kitchen countertop) are visible and must therefore be finished according to the selected configurations (chamfers, finishes).

This is a rough cut to allow for the installation of the socket.

Cooker/washbasin holes are processes that can be applied to a kitchen/bathroom countertop, there are different types:

Out-of-square means that the required cut is not perpendicular to the sides but is oblique. A and B indicate on which side the out-of-square cut is made.